The operator sets the tube into the fixture. Using this a formal generalization of the concepts and methodologies of fixture design for Tinker will be.

Design Principles Of Jigs And Fixtures Prescient Technologies

50 Checking FixtureGauge Design Requirements 501.

. These standards are intended as a guide for the construction of checking fixturesgages for Daimler Trucks North America LLC DTNA. Fixture design deals with the establishment of the basic fixture concepts. Jig and fixture design basics.

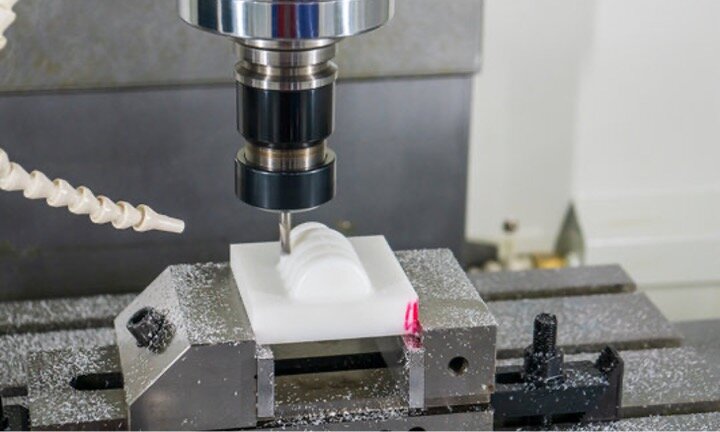

This paper prese nted a fixture layout design shown in fig. Fixture Design Fundamentals of Tool Design Study Guide DV07PUB3 - 4 - Review Questions 1. The check fixture is a form of gage.

21 and clamping f orce optimization procedure bas ed on. Check Fixture Tooling Standards This Gage Standard is designed as a guide for the design and building of checking gages suitable for our products this guideline is to be. Currently we have 12 members on our design department2 of them are senior engineers who are experienced in checking fixture industries.

Always aim at having a fixed rigid part of the fixture element to take up the cutting forces. The optimization procedure is multi. Checking fixturesgages must be handled and.

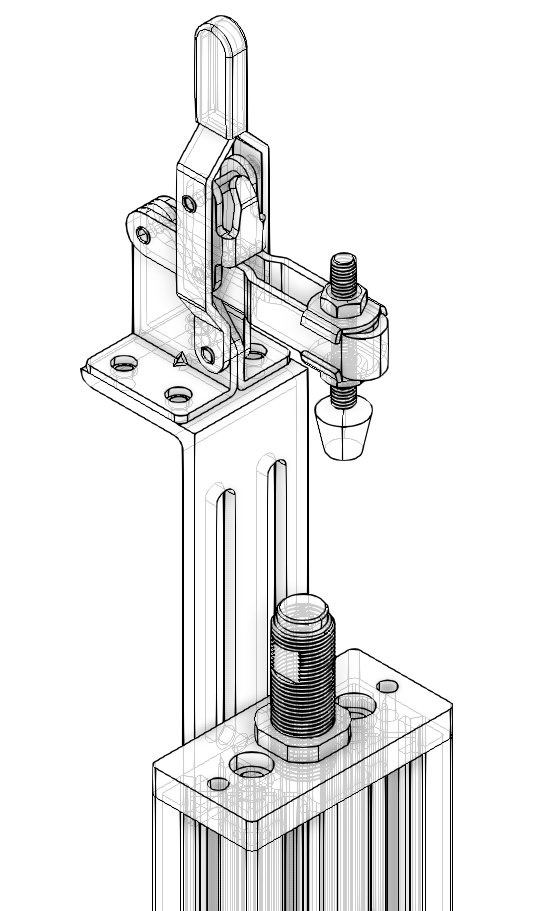

Checking fixture design guidelines Ditulis Margaret Lawson Kamis 19 Mei 2022 Tulis Komentar Edit. Supporting Positioning and Clamping. A check fixture differs from a jig in that the jig is essentially a holding device to hold the.

The Checking Fixture or Gauge design information is the property of ABC Technologies or their Customer. A fixture having the added function of guiding a tool is called a. To set forth guidelines for quoting check fixtures and a minimum standard for construction of new check fixtures.

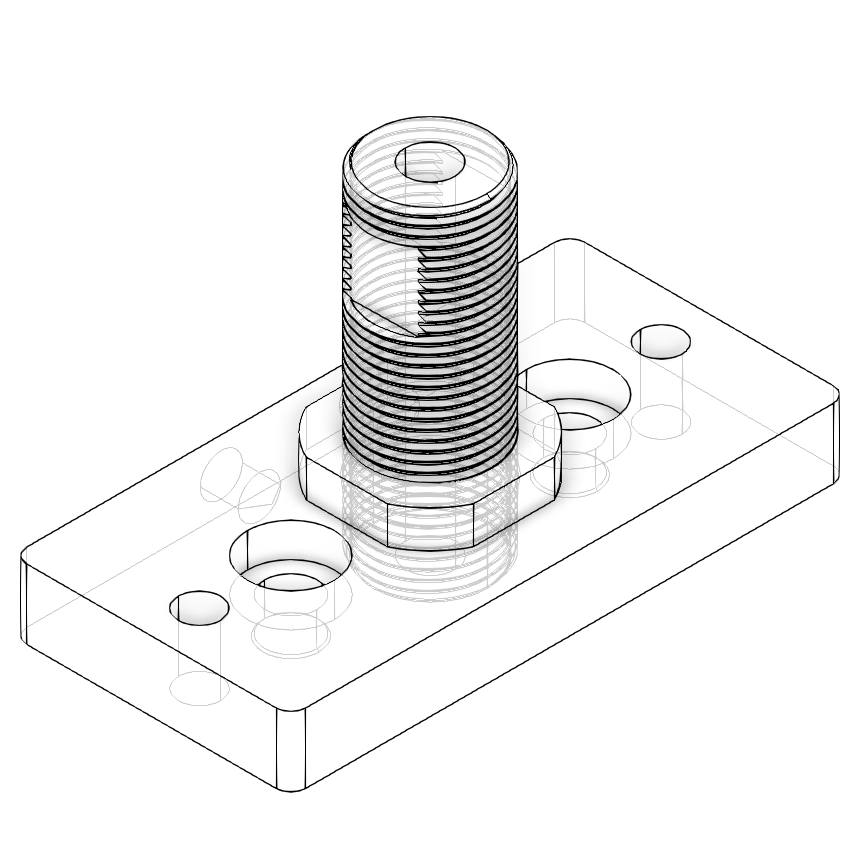

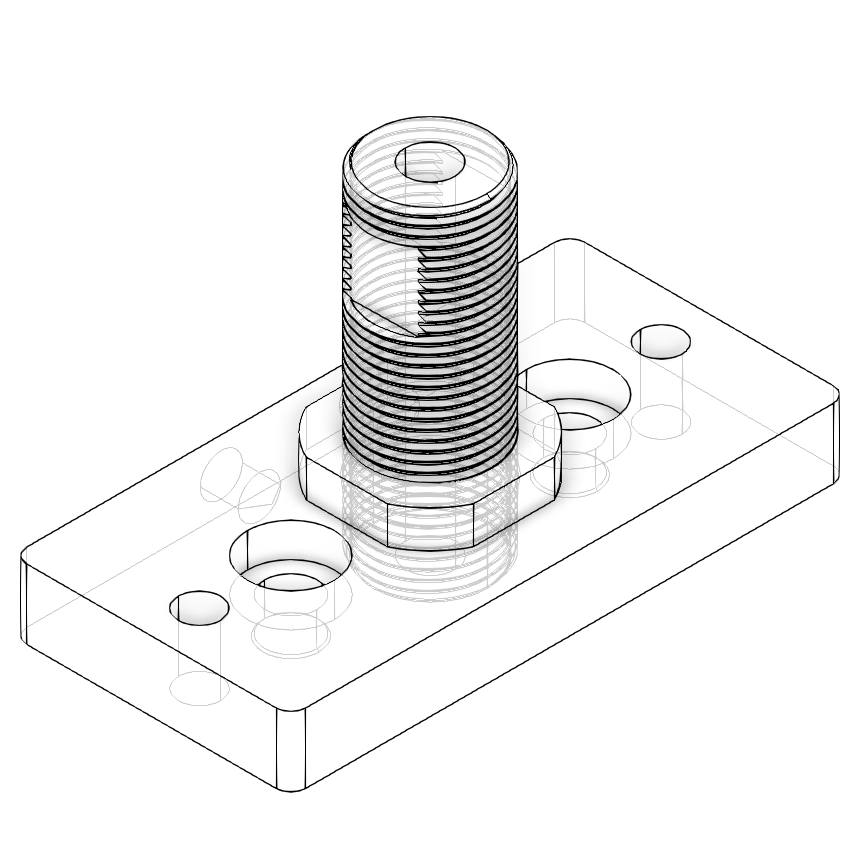

It is required for the Gauge Supplier to send the 3D and 2D CAD data in native format ie. Fixture layout is an embodiment of the concepts in the form of a spatial configuration of the fixture Fixture. Any object in space has six degrees of freedom.

Any deviation from these standards without the written authorization. The key to manufacturing jigs and fixtures starts with understanding how degrees of freedom work. Standard size of sphere to be 120 mm in diameter and 120 mm distance from center to shoulder mounted on.

Solid Works Mechanical Desktop Pro-E Catia V5 NX of the Checking Fixture or Gauge or. 61 All checking or holding fixtures must have 3 Tooling Bushings Tool Balls. 80-ENG-D-413 Checking Fixture Gauge Standard 0-07Jul2020.

Phase I 2 actual practical development at Tinker will be drawn. Locating a part to be machined involves mainly three steps. Final details are decided final drawings are made and the.

The final phase of the fixture-design process consists of turning the chosen design approach into reality. The GA and FEM. If it slips into the fixture and isnt held up by any interference its a.

43 part alignment on the checking fixture 12 44 part fixation means 13 45 types of checking systems for the dimensions to be checked 15 46 manufacturing materials 19 47. UNIT 4 DESIGN OF FIXTURE Design of Fixture Structure 41 Introduction Objectives 42 Design of Fixtures 43 Types of Fixture and its Industrial Application 431 Vise Fixture 432 Milling. Base plate to be constructed of aluminum 1 thick with machined edges parallel to body or work lines and.

A check fixture takes just a few moments to use see Figure 1. Design Principles Fixture should be designed to have the least mass possible Weight limits on shaker table Fixture should be designed to be as stiff as possible No unnecessary vibrations. To the extent possible avoid using hydraulic.

Two main intentions when placing a job on a jigfixture are. A check fixture differs from a jig in that the jig is essentially a holding device to hold the piece part while work or inspection is performed. Take note of the following guidelines.

In addition to fixture type decisions often must be made as to allow for removable fixtures using some form of mass interconnect between the test instruments and the fixture. Success depends on details.

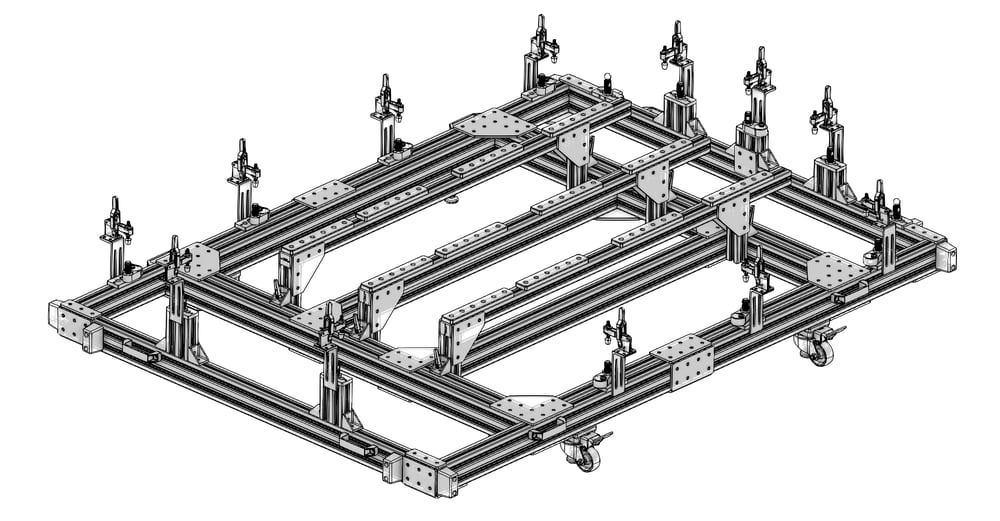

Designing Jigs And Fixtures Design Guide Vention

Designing Jigs And Fixtures Design Guide Vention

Jigs Vs Fixture Jigs Mechanical Design Fixtures

Practical Aspect On Fixture Design Calculation

Designing Jigs And Fixtures Design Guide Vention

Principles Of Location In Jig Fixture Design Carr Lane

Lighting Solutions How To Size And Hang A Chandelier Chandelier Makeover Lighting Solutions Chandelier

0 comments

Post a Comment